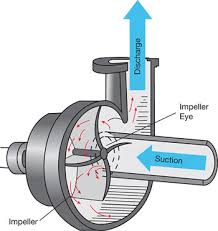

CENTRIFUGAL PUMPS

Fluid enters axially through eye of the casing, is caught up in the impeller blades, and is whirled tangentially and radially outward until it leaves through all circumferential parts of the impeller into the diffuser part of the casing. The fluid gains both velocity and pressure while passing through the impeller.

In partnership with SAWA PUMPEN, TRUE Pump offers the widest range of centrifugal pumping solutions for the Food, Beverage, Personal care and Pharmaceutical industries. All pumps are designed with the highest level of hygienic standards and are all available with a hermetically sealed Magnetically Driven Coupling for hazardous areas.

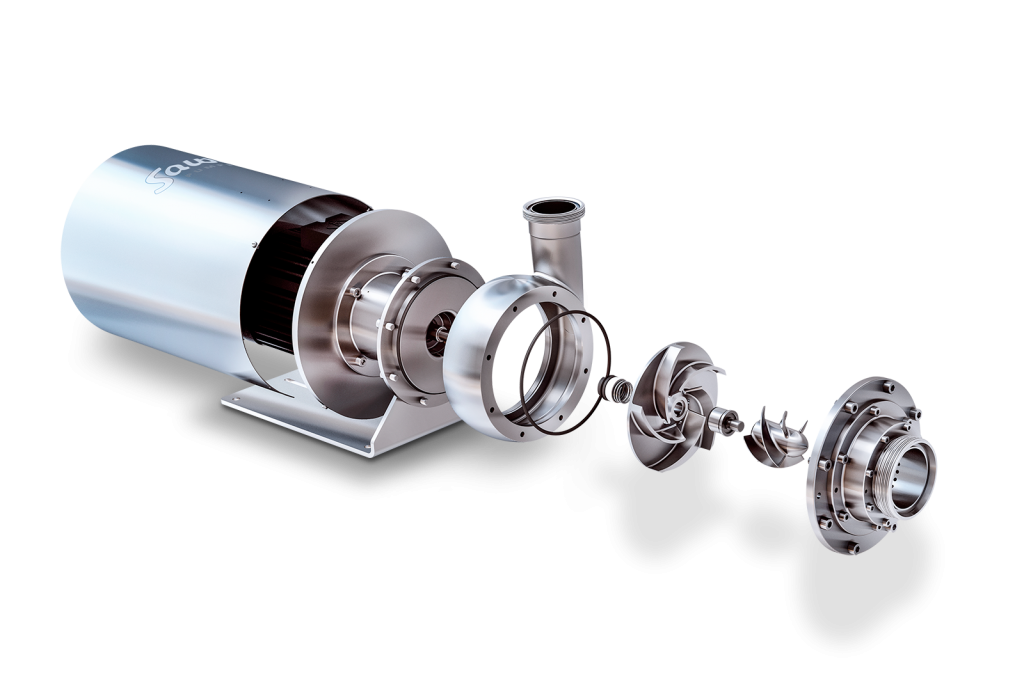

TRUE Centrifugal Pump LE

| Flow Rate Q | max. 240 m3/h |

| Delivery Head H | up to 90 m |

| Temperature Range | minus 30 °C to 130 °C, max. 150 °C (SIP) |

| Viscosity | up to approx. 500 mPas |

| Nominal Connections | PN10 to PN160 |

- Flow optimized by the volute casing and impeller designs with high efficiencies up to 75 %

- Dead space-free design (hygienic design)

- Very quiet operation

- CIP and SIP compliant

- Simple design/low maintenance costs

- Robust design comprising high-quality chromium- nickel-molybdenum stainless steel 1.4435/316L with electropolished surfaces

- Capable of pumping of solids-laden media with no risk of clogging

- Ideal for fast temperature changes thanks to sturdy design

- The robust design allows handling of abrasive and corrosive media

- Various mechanical seal systems available

- ATEX for zones 1, 2, 21 and 22

- Pharma design for maximum safety, reliability and hygiene (surface roughnesses down to Ra 0.4 μm

- Magnetic coupling hermetically sealed version LEM for crystallising, toxic, flammable and environmentally hazardous liquids

- Vertical installation for simple residual drainage

- Bearing housing for special requirements

- Inducer option available for low NPSHa values 1 m

- Jacketed Housing available to heat/cool with liquid or heating cartridge

- Complete draining at the lowest point of the pump

TRUE Liquid Ring Pump

| Flow Rate Q | max. 70 m3/h |

| Delivery Head H | up to 43 m |

| Temperature Range | minus 30 °C to 130 °C, max. 145 °C (SIP) |

| Viscosity | up to approx. 500 mPas |

| Nominal Connections | max. PN10 |

- Self-priming (suction head up to 7 m)

- Excellent pumping behaviour with liquids containing gas

- Bi-directional operation

- Quiet operation

- Dead space-free design (hygienic design)

- CIP and SIP compliant

- Simple design and easy seal change

- Low maintenance costs and long service life

- Sturdy design comprising high-quality chromium- nickel-molybdenum stainless steel 1.4435/316L with electropolished surfaces

- Gentle milk pumping without damaging fat

- Various mechanical seal systems available

- ATEX for zones 1, 2, 21 and 22

- Pharma design for maximum safety, reliability and hygiene (surface roughnesses down to Ra 0.4 μm)

- Magnetic coupling hermetically sealed version HDM for crystallising, toxic, flammable and environmentally hazardous liquids

- Bearing housing for special requirements

- Jacketed Housing available to heat/cool with liquid or heating cartridge

- Complete draining at the lowest point of the pump

TRUE Hybrid Centrifugal

| Flow Rate Q | max. 100 m3/h |

| Delivery Head H | up to 70 m |

| Temperature Range | minus 30 °C to 130 °C, max. 145 °C (SIP) |

| Viscosity | up to approx. 100 mPas |

| Nominal Connections | max. PN10 to PN63 |

- Flow optimised volute casing and impeller designs with high efficiencies up to 72 %

- Dead space-free design (hygienic design)

- Excellent behaviour with liquids containing high concentration of gas

- Very quiet operation

- CIP and SIP compliant

- Simple design/low maintenance costs

- Sturdy design comprising high-quality chromium- nickel-molybdenum stainless steel 1.4435/316L with electropolished surfaces

- Ideal for fast temperature changes thanks to sturdy design

- Option for various mechanical seal systems

- Completely drainable

- Inducer included to reduce NPSHr

- plug-in shaft for the use of norm motors

- ATEX for zones 1, 2, 21 and 22

- Pharma design for maximum safety, reliability and hygiene (surface roughnesses down to Ra 0.4 μm)

- Magnetic coupling hermetically sealed version LESM for crystallising, toxic, flammable and environmentally hazardous liquids

- Bearing housing for special requirements

- Complete draining at the lowest point of the pump

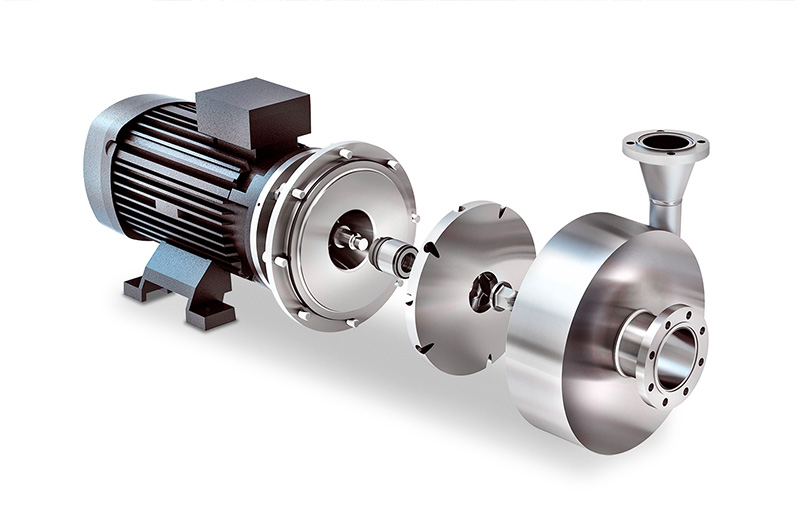

TRUE Centrifugal Pump HP

| Flow Rate Q | max. 100 m3/h |

| Delivery Head H | up to 100 m |

| Temperature Range | minus 30 °C to 130 °C, max. 145 °C (SIP) |

| Viscosity | up to approx. 500 mPas |

| Nominal Connections | PN10 to PN100 |

- Dead space-free design (hygienic design)

- Very quiet operation

- CIP and SIP compliant

- Simple design/low maintenance costs

- Sturdy design comprising high-quality chromium- nickel-molybdenum stainless steel 1.4435/316L with electropolished surfaces

- Pumping of liquid with heavy solids content with no risk of clogging

- Ideal for fast temperature changes thanks to sturdy design

- The sturdy design allows handling of abrasive and corrosive media

- Option for various mechanical seal systems

- High delivery head with a single stage pump

- Plug-in shaft for the use of norm motors

- ATEX for zones 1, 2, 21 and 22

- Pharma design for maximum safety, reliability and hygiene (surface roughnesses down to Ra 0.4 μm)

- Magnetic coupling hermetically sealed version ZALM and ZAM for crystallising, toxic, flammable and environmentally hazardous liquids

- Vertical installation for simple residual drainage

- Bearing housing for special requirements

- Jacketed Housing available to heat/cool with liquid or heating cartridge

- Complete draining at the lowest point of the pump