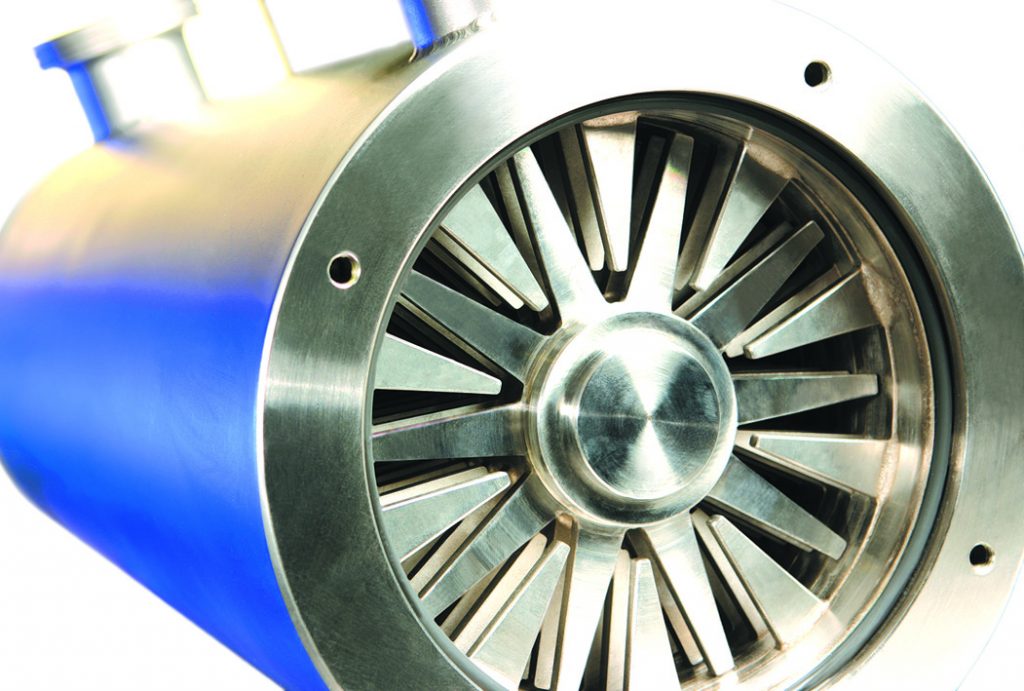

LIQUID - GAS MIXING

Whether you are aerating a fat mass with CO2 or injecting steam to cook a processed cheese, the INFINI-MIX Liquid – Gas mixers will thoroughly disperse the gas into the liquid for the perfect mixing result.

Using the DLM/S series mixer to cook with steam is the most efficient use of direct steam injection. Unlike a thermal/static mixing valve, the dynamic mixing elements on the DLM/S thoroughly disperse the steam meaning a uniform, consistent product that is taking advantage of 100% of the thermal properties of the steam. This allows you to use much lower pressure and volume of steam and the saves you money!

The more delicate DLM/M series mixer can be used for direct steam injection for cooking products with large particles to maintain the highest levels of product integrity.

Additionally, the jacketed housing can be cooled to ensure there is no “burn-on” inside the mixer. This allows you to run indefinitely!

Using the DLM/S for product aeration has a wide range of benefits over traditional aeration methods. The efficient dispersion of the gas throughout the product allows us to aerate at lower pressures and at lower rotational speeds than our competition.

Aerating a fat mass at lower rotational speeds translates into higher product integrity and longer shelf-life when you arte not damaging the fats and causing separation.