POSITIVE DISPLACEMENT PUMPS

There are many types of positive displacement pumps. All have their advantages and disadvantages. Some pumps have capabilities that far surpass the capabilities of most others and some are very basic fluid transfer solutions. What pumping technology and manufacturer is best for your application?

Below is a brief summary of all of the different types of positive displacement pumps found in the Hygienic processing world. North American Process, Inc. is happy to help you select the pump that best suits your application and your budget.

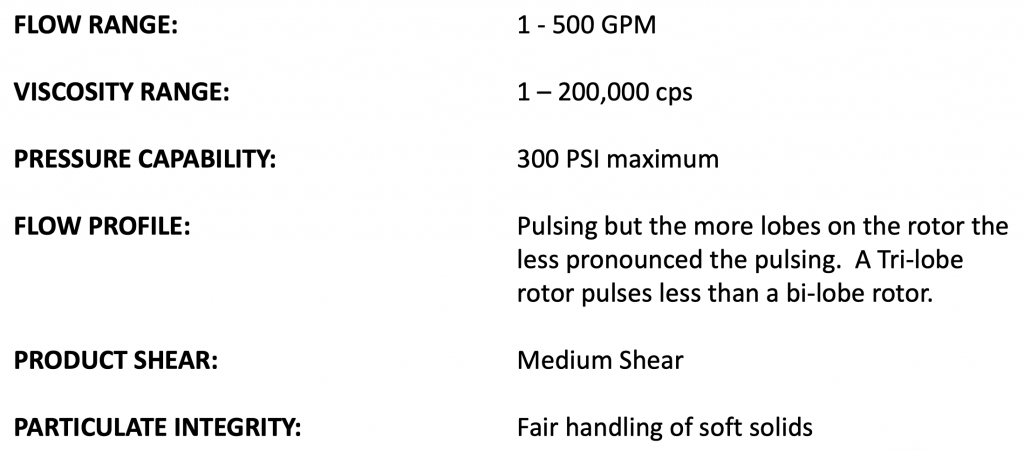

ROTARY LOBE

Principle of Operation

The movement of the counter rotating rotors creates a partial vacuum that allows atmospheric pressure or other external pressures to force fluid into the pump chamber. As the rotors revolve, an expanding cavity forms, filling with fluid. As the blades disengage, each dwell forms a cavity. As the rotor blades engage, the cavity diminishes and fluid is, displaced into the outlet port.

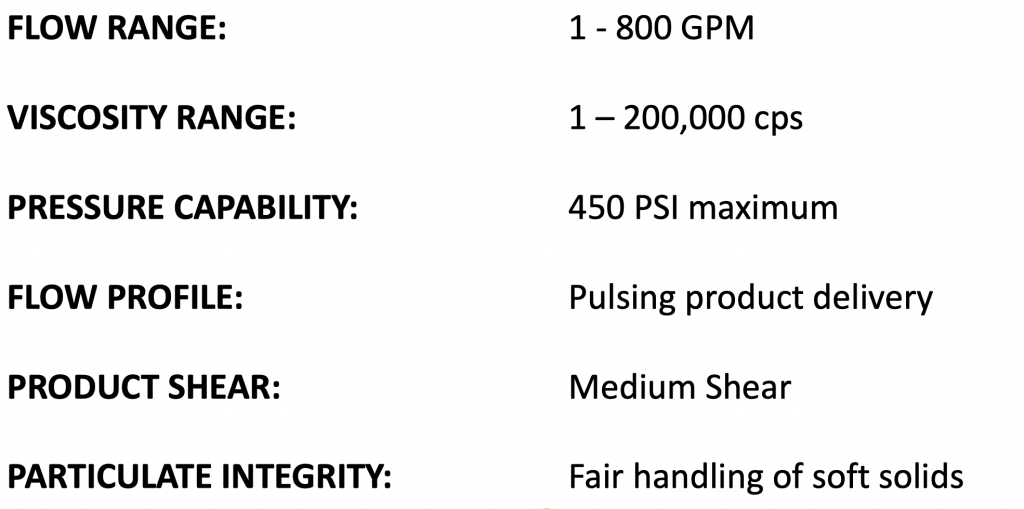

CIRCUMFERENTIAL PISTON

Principle of Operation

As the circumferential piston rotates on the inlet side, the expanding volume draws the liquid into the pump. The liquid is forced out the discharge port by the collapsing cavity on the discharge side.

Different from a Rotary Lobe pump, the tolerances between the rotors and the housing are tighter and shaped to “sweep” or “shovel” liquids with particulates.

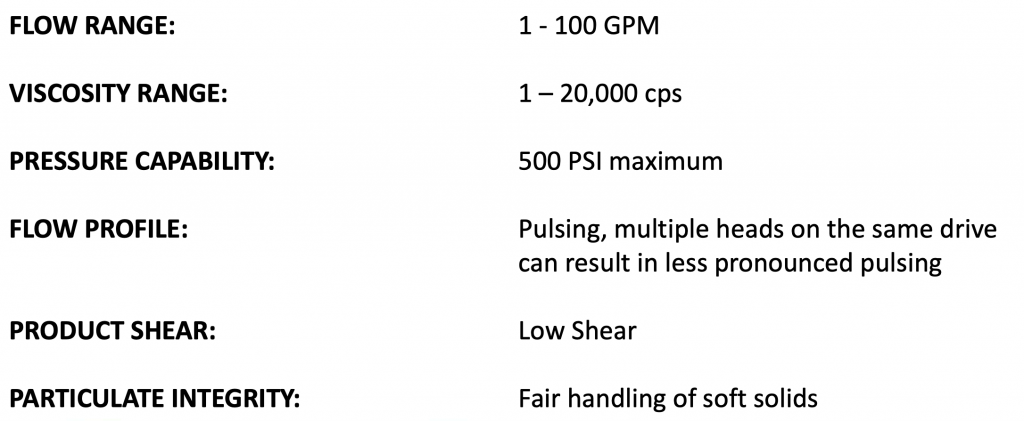

METERING PUMPS

Principle of Operation

A metering pump moves a precise volume of liquid in a specified time period providing an accurate volumetric flow rate. Delivery of fluids in precise adjustable flow rates is sometimes called metering.

The reciprocating plunger and adjustable stroke length with reverse facing check-valves allows the pump to act as a combination of a pump and flowmeter.

Multiple heads can be used on the same drive for continuous blending.

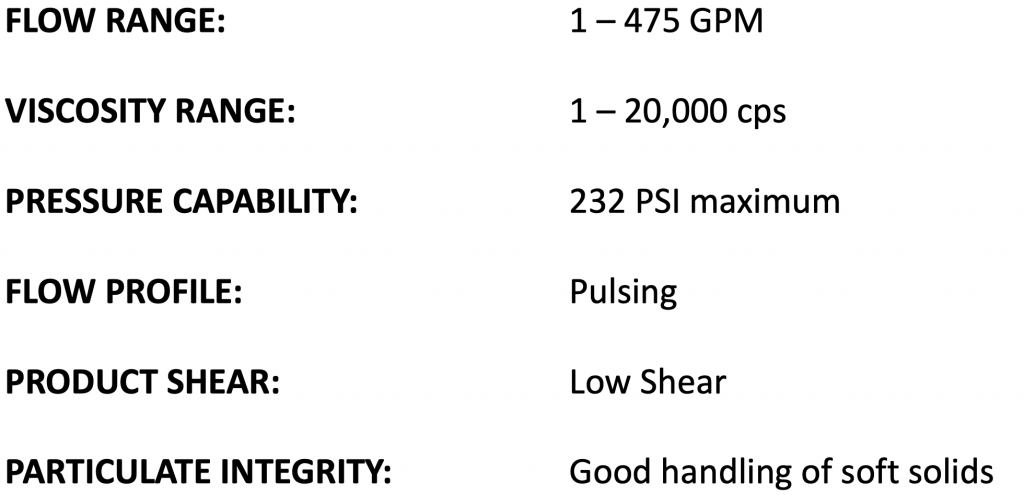

PERISTALTIC PUMPS

Principle of Operation

A peristaltic pumps are also commonly known as roller pumps. The fluid is contained within a flexible tube fitted inside a circular pump casing.

A rotor with a number of “rollers”, “shoes”, “wipers”, or “lobes” attached to the external circumference of the rotor compresses the flexible tube. As the rotor turns, the part of the tube under compression is pinched closed thus forcing the fluid to be pumped to move through the tube.

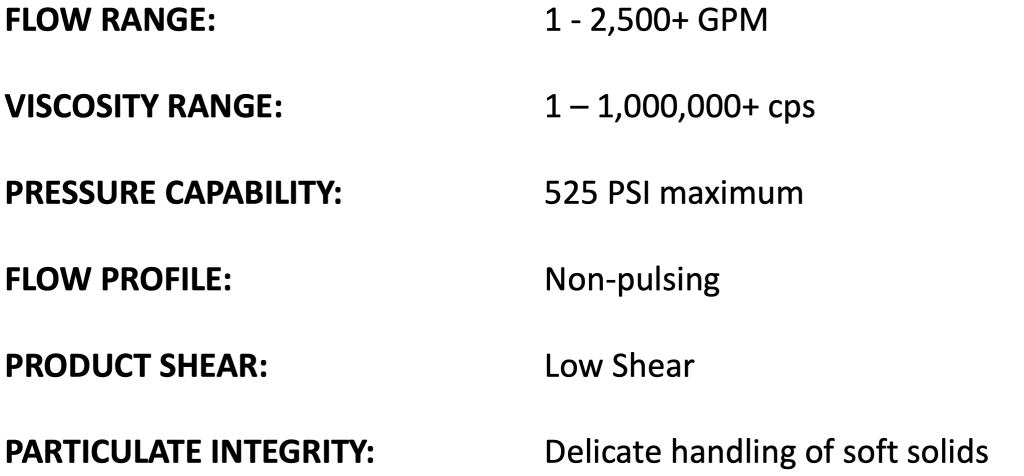

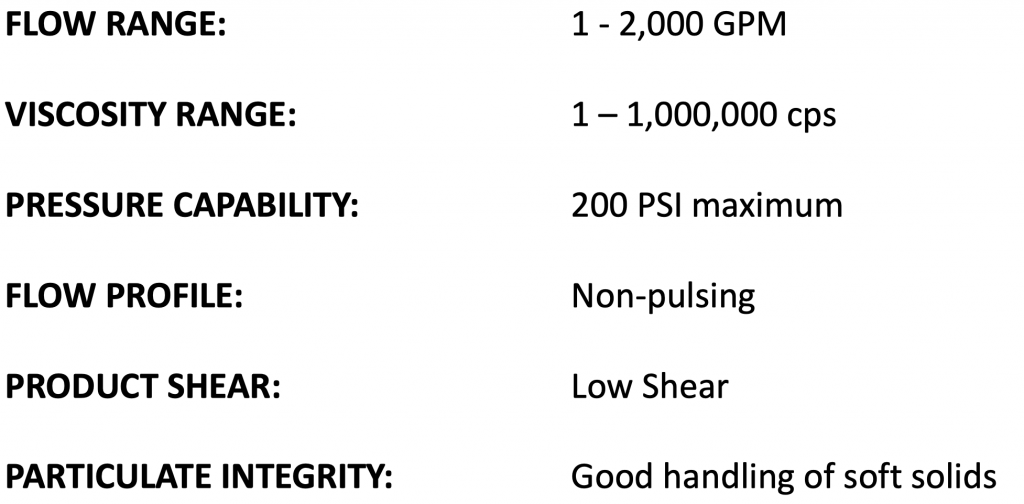

PROGRESSIVE CAVITY PUMPS

Principle of Operation

A progressive cavity pump is often referred to as a “screw pump”. It is made up of a contacting rotor and stator that transfers fluid by means of the progress through the pump of a sequence of small, fixed shape, discrete cavities, as the rotor turns. This leads to the volumetric flowrate being proportional to the rotation rate (bidirectionally) and to low levels of shear being applied to the pumped fluid.

TWIN SCREW PUMPS

Principle of Operation

The fundamental concept of the two-screw pump is the use of two intermeshing, non-contacting screws, synchronized by timing gears‚ thereby permitting the screws to convey a liquid without any metal to metal contact. The tight tolerances between the screws and housing in combination with the axial flow of the product ensures a laminar flow and low shear product handling.

This unique concept allows the pump to handle virtually any Newtonian or non-Newtonian fluid under a wide variety of conditions‚ including multiple phases (i.e.‚ gas and solids)‚ elevated temperatures and intermittent dry operation.